Unique Bridge Mill CNC Combines Features of Vertical & Double Column Machining Centers

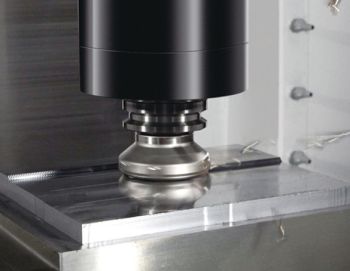

Okuma has announced an expansion to its line of CNC metal cutting machines with the debut of a new bridge-style machining center -- the MB-80V. This new product offers extreme machining flexibility due to its uniquely combined vertical and double-column machining capabilities.

The sophisticated design of the MB-80V is based on Okuma's double-column machining center platform, complete with moving table functionality. With this durable platform as a foundation, the Okuma product development team added an integrated vertical spindle to the design, making the MB-80V one of the industry's few true bridge mill machines. Other design features of the MB-80V include:

- A large working table size to accommodate larger work pieces -- 63" x 41"

- Compact footprint commands less floor space than similar models

- Two integrated spindle options: CAT40 BIG-PLUS® /HSK63 or CAT50 BIG-PLUS®

- Thermal controls throughout the entire machining process

- Cyclonic filtration system

- Smart ergonomic design allows for easy table and spindle access

These features afford a series of machining benefits including: minimized cycle times due to a combination of cutting capabilities within one bridge mill machine; easy access to key machining areas by the operator for quicker set-up times; and maximum production capabilities due to the performance of the machine spindle.

The MB-80V was designed in response to the market need for a high-performance, highly versatile CNC machine for applications most commonly found in die-mold, automotive, aerospace, and semiconductor industries.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::